ProductionTargetIntro

Introduction

The job of the Production Target is to intercept the proton beam to produce large numbers of pions because 99% of pions produce muons, which are the particles of interest to Mu2e. We construct the Production Target from a dense material and place it directly in the path of the incoming proton beam. To reduce the probability of the pions being reabsorbed before leaving the material, we make the target small - about the size of a standard pencil.

Requirements

The requirements for the production target are given in Mu2e document 887 [1]. The Production Target generates pions that decay to muons as they are transported to the stopping target in the Detector Solenoid. The target is installed inside the bore of the Production Solenoid within a graded magnetic field, a configuration designed to maximize the production and capture of low-energy negative pions generated by interaction with the 8 GeV primary proton beam. The pion production cross section of the target material must be large enough to allow Mu2e to produce the required number of stopped muons. Pion production is maximized with a dense, high atomic number material to ensure a high rate of beam-target interactions. A compact target geometry minimizes pion reabsorption. The refractory metal tungsten is ideal, since at the design beam power of 8 kW it is able to directly radiate the generated heat load to the solenoid shield without the need for a coolant.

The production target must function in a harsh environment presenting a number of technical challenges including resistance to intense proton irradiation, continuous thermal cycling at ultra-high temperature and resistance to chemical effects due to interaction with residual gasses in the vacuum. The minimum acceptable target lifetime has been specified as one year, during which the target must maintain its mechanical integrity and positional alignment to the beam. The specification for the vacuum level is 1 × 10-5 Torr. The risk section below reviews the impact of the vacuum level on the target lifetime.

The target must be firmly supported by a structure that is stiff and minimizes vibrations. The impact of pion reabsorption on stopped muons suggests a structure that is low mass, and presents a small geometric profile to the spiral trajectories of pions within the Production Solenoid. The support system also enables remote installation, removal and exchange of the target and offline adjustment of the target rod position within its support structure.

Given the choice of beam and target size to optimize the stopped muon yield, overall alignment of the target rod with respect to the beam needs to be less than about 0.5 mm to avoid losing more than a few percent of the muon yield. When the first target is installed it must be placed close enough to the theoretical beam position that the beam can be steered onto the target. The target support structure and remote handling system must ensure replacement targets are placed within about ±0.25 mm of the first. In addition, the target position must be stable to about ±0.25 mm during operation, taking into account distortions due to thermal cycling from ambient conditions when the beam is turned on.

The incoming primary beam can be adjusted to give ±1 cm in both the vertical and horizontal directions at the target. The angle of the beam can also be varied in both planes to ±0.8°. Changes beyond this range will require an adjustment of the relative alignment of the beamline and the Production Solenoid.

Technical Design

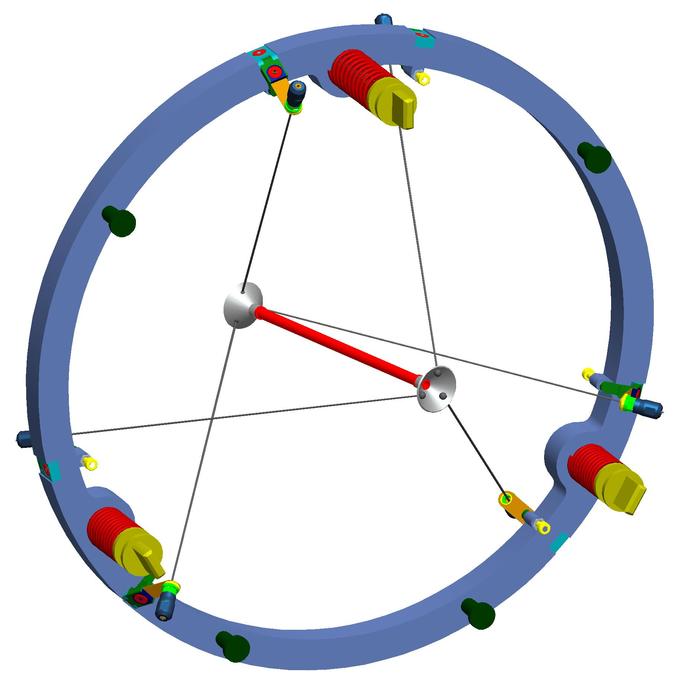

The proposed Mu2e pion production target is a radiation-cooled tungsten rod, the size and shape of a pencil, and is described in detail in Mu2e document 2406. The 160 mm long, 6.3 mm diameter rod is mounted from a structure that resembles a bicycle wheel, consisting of conical tungsten target end ’hubs‘, spring-loaded refractory metal spokes and a titanium outer support ring as shown in Figure 1. Also shown are the three spring-loaded clamps and four handling lugs that form part of the remote handling/mounting system. The target assembly fits inside the 400 mm diameter clear bore of the production solenoid vacuum vessel.

The target will be made from stock tungsten rod that is produced via the powder metallurgy process. Impurities will be limited such that the material will be at least 99.95% pure tungsten (as is the case in the present neutron spallation target at the ISIS facility in the UK) and will have a bulk solid fraction of at least 97%. During production the material is pressed, sintered then swaged and then ground to size. Tungsten is chosen as the target material primarily for its excellent high-temperature mechanical properties, which allow the target to run hot enough that it may be cooled radiatively. Of the pure refractory metals, tungsten has the highest melting point, highest tensile strength and lowest thermal expansion coefficient, making it extremely well suited to applications that involve thermal cycling to ultra-high temperatures. Its high thermal conductivity reduces temperature gradients and consequent thermal stresses and distortions. The purpose of the end hubs is to facilitate joining of the support spokes to the target rod. They are designed in such a way that this connection is placed outside the beam footprint to separate the end of the spoke from the hottest part of the target. The target end hubs will also be made from tungsten to avoid the potential for differential thermal expansion at the interface. The end hubs will either be separate parts that are mechanically fitted to the ends of the target rod, or possibly machined along with the target from a single piece of material to prevent any chemical corrosion/erosion from occurring at that interface.

Six refractory metal support spokes, that are approximately 1 mm in diameter and 250 mm long, form a low-mass target support structure that is designed to minimize the reabsorption of useful pions generated by the target. A pre-tension in the spokes ensures good rigidity in the structure. At their ‘hot’ end, each spoke is threaded through a hole in one of the hubs, and incorporates a ‘ball’ feature that mechanically stops the spoke from pulling through while allowing a range of angular positions. A collet chuck arrangement grips the plain ‘cold’ end of the spoke where it interfaces with a tensioner mechanism. The spoke materials under consideration are tungsten, tantalum, and alloys of those materials. While tungsten appears to have a superior resistance to high temperature creep, it also suffers from a ductile-to-brittle transition at around 300°C. Tantalum, on the other hand, remains ductile throughout the full range of temperatures of interest. A number of tungsten alloys that have been specially formulated to give high temperature creep resistance are also under consideration. The final choice will be influenced by practical manufacturing constraints as well as a need for good high-temperature creep resistance. A number of spoke manufacturing methods are under consideration, including a rotary wire EDM process whereby the spoke, complete with its spherical end feature, is produced from a single bar.

[1]R. Coleman, K. Lynch, J. Popp, “Production Target Requirements,” Mu2e-doc-887